Testing Facilities

Investing in test equipment and working with key partners allows us to complete projects quickly. We can test your product and use our experience to diagnose and solve any problems.

- Environmental Testing

- Thermal Testing

- IP Testing

- Vibration Testing

- Impact Testing

- Certification Testing

- EMC Pre-compliance

- Electronics Reliability Testing

- Electronics Performance Testing

Environmental Testing

Whilst a lot of product and component testing can be carried out at room temperature, it is also important to perform testing at the operational extremes. For instance, it might be that whilst a drive system runs freely at room temperature, it seizes at high temperature or a power supply may not start up at very low temperatures. The capacity of batteries is very dependant on temperature and the properties of non-metallic materials can change significantly with humidity and temperature so it is important to understand this and test accordingly.

Our environmental chamber can produce temperatures in the range -75 to 180 °C (-103 to 356 °F) and relative humidity up to 90% enabling parts and assemblies to be tested to their limit.

EMC Pre-compliance and Diagnostics

EMC compliance is a headache that most electronic engineers will be all too familiar with. Time spent in a test facility is expensive and you often don’t get the support you need in solving issues that arise.

Our in-house equipment and experienced engineers allow us to assess, improve and diagnose EMC compliance so that any issues can be discovered and resolved quickly. We always recommend performing pre-compliance at an early design stage where changes are still easily made so that full compliance can be approached with confidence.

Impact Testing

The aim of impact testing is to determine how much impact energy an enclosure can withstand. Testing is generally carried out to IEC/EN 62262 and an impact rating given as an IK value from 00 to 10 with 00 meaning very low and 10 meaning very high impact resistance.

| IK Code | IK00 | IK01 | IK02 | IK03 | IK04 | IK05 | IK06 | IK07 | IK08 | IK09 | IK10 | IK11 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Impact Energy (Joules) | * | 0.14 | 0.2 | 0.35 | 0.5 | 0.7 | 1 | 2 | 5 | 10 | 20 | 50 |

Not all standards follow the IK system but the same principles apply. For instance in hazardous areas (ATEX and IECEx) compliance, EN/IEC/UL 60079-0 specifies the impact test method and resistance requirement slightly differently.

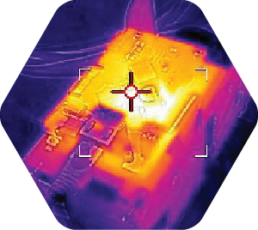

Thermal Testing

There are two aspects to thermal testing – safety and reliability. Parts which are readily accessible must be kept below the temperature at which they may cause burning to an operator and insulation materials must be operated within their capability to prevent them from breaking down.

The reliability and longevity of electronic assemblies can be directly attributed to the temperatures parts are running at. Semiconductor junction temperatures must be kept below their specified absolute maximums and passive components must be operated within their limits.

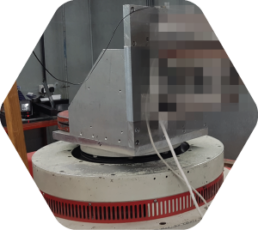

Vibration Testing

Vibration testing simulates the conditions a product may encounter in use to uncover any resonances in an assembly which may cause catastrophic failure or more trivial issues like fasteners coming loose. Electronics can also be affected by vibration – for instance, bulky components may need additional mechanical support to protect against solder joint fatigue.

The product to be tested is rigidly bolted to a vibrating table and random or sinusoidal vibrations are applied at a defined amplitude to simulate different scenarios. Frequency sweeps can be carried out to find the product’s resonant frequencies where it is most likely to fail.

IP Testing

Ingress Protection (IP) testing checks an enclosure’s ability to restrict the entry of foreign objects such as solid particles or fluids. Testing is generally carried out to EN/IEC 60529 and an IP code in the form IPxx is assigned. The first digit refers to the protection against solid objects and the second digit refers to the ability of an enclosure to withstand water and jets.

Products for North American markets are usually tested and specified differently to UL 50E, NEMA 250 or CSA22.2 No. 94 and given a “TYPE” designation. One or more suffixes can be added to some of these classifications to add further specification.

| IP Numeral | Protection Against Solid Objects (First Numeral) | Protection Against Water (Second Numeral) |

|---|---|---|

| 0 | Not protected | Not protected |

| 1 | ≥50 mm diameter | Vertical dripping |

| 2 | ≥12.5 mm diameter | Dripping (15° tilted) |

| 3 | ≥2.5 mm diameter | Spraying |

| 4 | ≥1.0 mm diameter | Splashing |

| 5 | dust-protected | Jetting |

| 6 | dust-tight | Powerful jetting |

| 7 | - | Temporary immersion |

| 8 | - | Continuous immersion |

| Enclosure Type | Enclosure Location | Protection from Foreign Objects | Protection from Water | Other Protection | Optional Suffixes |

|---|---|---|---|---|---|

| TYPE 1 | Indoor use | Falling dirt | None | ||

| TYPE 2 | Indoor use | Falling dirt | Dripping and light splashing | ||

| TYPE 3 | Indoor or outdoor use | Falling and windblown dust | Rain, sleet and snow | R, S, X, RX, SX | |

| TYPE 4 | Indoor or outdoor use | Falling and windblown dust | Rain, sleet, snow, splashing water and hose-directed water | X | |

| TYPE 5 | Indoor use | Falling dirt and settling airborne dust, lint, fibres and flyings | Dripping and light splashing | ||

| TYPE 6 | Indoor or outdoor use | Falling dirt | Rain, sleet, snow, splashing water, hose-directed water and occasional submersion at limited depth | P | |

| TYPE 12 | Indoor use | Falling dirt and circulating dust, lint, fibers, and flyings | Dripping and light splashing | Light splashing of oil and non-corrosive coolants. | K |

| TYPE 13 | Indoor use | Falling dirt and circulating dust, lint, fibers, and flyings | Dripping and light splashing | Spraying, splashing, and seepage of oil, and non-corrosive coolants |

Where a TYPE designation has optional suffixes, they have the following meanings:

K – enclosures constructed with knockouts

R – enclosure with ventilation (providing protection against falling dirt only)

S – enclosures where external mechanisms remain operable when ice laden

X – enclosures providing an increased level of protection against corrosion