Although technically similar, there are significant differences between ATEX and IECEx Certification, that must be understood when designing products and looking to gain Hazardous Area Ex Equipment Certification.

ATEX vs IECEx Summary

The first important difference between ATEX and IECEx certification is geographic coverage. ATEX certification is EU based, whereas IECEx certification is valid globally. As a result, end users recognise and accept IECEx certification more widely than ATEX certification.

ATEX and IECEx Directives and Schemes

Both ATEX and IECEx have several components but ATEX has only two Directives, whereas IECEx has four Schemes.

ATEX Directives:

- Directive 2014/34/EU (also known as ATEX 114 or ATEX Equipment Directive)

- Directive 99/92/EC (also known as ATEX 137 or ATEX Workplace Directive)

IECEx Schemes:

- IECEx Certified Equipment Scheme

- IECEx Certified Services Scheme

- IECEx Conformity Mark Licensing System

- IECEx Certified Competent Persons Scheme

The text that follows is written from the perspective of equipment certification.

ATEX Fundamentals

ATEX is a Legal Regulatory Framework that applies within the European Union. Short for ATmosphères EXplosible, it applies to the manufacture of all equipment for use in potentially explosive environments.

According to the ATEX Working Group: The objectives of ATEX are to permit the free movement of products within the internal market whilst ensuring a high level of protection of health and safety.

The ATEX Directive dictates compliance with the Essential Health and Safety Requirements (EHSR). Therefore, complying with relevant standards can satisfy these requirements. It is not mandatory that products are compliant with specific standards, but it is the common approach.

IECEx Fundamentals

IECEx is a voluntary certification scheme controlled by the International Electrotechnical Commission’s standards (IEC). The name IECEx is derived from International Electrotechnical Commission Explosive.

According to IEC: The objective of the IECEx System is to facilitate international trade in equipment and services for use in explosive atmospheres, while maintaining the required level of safety.

IECEx is not a regulatory framework, it is a standards-based scheme. Full compliance with the IEC Standard listed on the IECEx Certificate is mandatory.

ATEX Notified Body

To comply with ATEX Directives, for high-risk hazardous areas, it is a legal requirement to engage a third party body. This body is Notified to the European commission by a National Government to perform actions in relation to a directive. Known as an ATEX Notified Bodies Group (ExNBG). Also commonly known as an ATEX Notified Body (NB).

IECEx Approved Certification body

Organisations that have completed the IECEx assessment process and are approved to operate within the IECEx Certified Equipment Scheme, are known as an IECEx Approved Certification Body (ExCB). Accompanied by IECEx Approved Test Laboratories (ExTLs), they can issue documents and testing for manufactures to gain IECEx Equipment Certification.

ATEX Notified Bodies and IECEx Certification Bodies are often the same entity, so manufactures can use them to gain both approvals.

ATEX EU Type Examination Certificate

A Notified Body will perform evaluation and product testing to the applicable standards. They will then issue an EU Type Examination Certificate, to show the equipment compliance. Products designed for lower risk hazardous area classifications, Category 3 Electrical and Category 2 Mechanical, may not require inspection by a Notified Body. Instead manufactures may use self-certification, but still require the issue of a manufacturer’s EU Declaration of Conformity.

IECEx Test Reports ExTR

IECEx Test Reports are a pack of documents completed and issued by the manufacturer’s appointed ExTL, for endorsement by an ExCB. They detail the results of sample product testing, showing that the examined product type is in conformity with specified Standards. Unlike under ATEX these requirements are regardless of the product risk category. There is no self-certification under the IECEx Scheme.

An ATEX EU Type Examination Certificate can be based on an ExTR, but an ExTR cannot be based on an ATEX EU Type Examination Certificate.

ATEX Quality Assurance Notifications (QAN)

In line with the EU Type Examination Certificate requirements above, for equipment intended for use in high-risk areas, Categories M1 & 1 or Categories M2 & 2 for electrical equipment, the manufacturer needs to engage an NB to gain ATEX Quality Assurance Notification (QAN).

The Quality Assurance Notification requirements are specific relevant additions to ISO 9001 quality systems. The purpose of the QAN is to ensure the ongoing monitoring of systems and processes in relation to the manufacture of ATEX equipment. The requirement for audits is every 18 months if the manufacturer has ISO 9001 certification, or every 12 months if they have not.

IECEx Quality Assessment Report

Legally, IECEx Equipment manufacturers must have a suitable quality management system that meets ISO-9001, and the full requirements of the IECEx scheme. The annual audit of the manufacturer’s quality system by an ExCB produces a document called the IECEx Quality Assessment Report (QAR). Again, unlike under ATEX, these requirements are regardless of the product risk category.

Both inspections are effectively the same and IECEx QAR can support the issue of an ATEX QAN.

ATEX EU Declaration of Conformity

The EU Commission governs the permission for suppliers to offer Ex products for sale in the EU. This is based on the seller’s declaration of product compliance with the Essential Health and Safety Requirements of the ATEX Directive. This declaration is called the EU Declaration of Conformity (DoC). It is a statement produced by the equipment manufacturer that declares, on the sole responsibility of the manufacturer, that they have all the necessary documentation and evidence to meet the ATEX directive. Additionally, this includes a QAN to cover the factory inspections.

IECEx Certificate of Conformity

Unlike the ATEX EU Declaration of Conformity, an IECEx Certificate of Conformity (CoC) is not issued by the equipment manufacturer but instead is issued by an ExCB. An IECEx Certificate of Conformity states that a sample of the Ex product, described on the Certificate, has been independently tested and found to comply with the International Standards listed in the Certificate. It attests that there is a suitable ExTR and QAR in place to meet the full IECEx requirements.

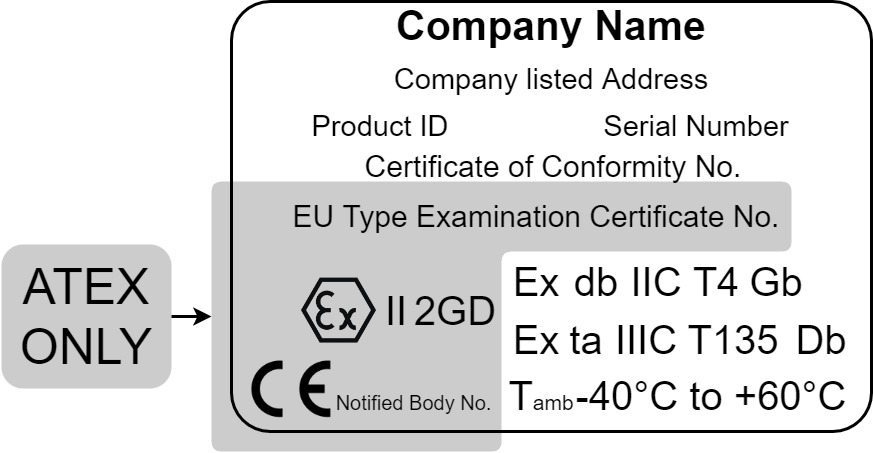

ATEX and IECEx Product Markings

ATEX and IECEx Product Markings require very similar components including:

ATEX and IECEx Product Markings require very similar components including:

- Manufacturer details

- Product identification

- Protection Concept(s)

- Gas and/or Dust groups

- Equipment Protection Levels (EPL)

- Electrical parameters

- Multiple temperature requirements

Both certifications’ product markings include their certificate number; for ATEX this is the EU Type Examination Certificate number and for IECEx it is the Certificate of Conformity number.

Because it is an EU based framework, ATEX also requires CE marking on all products, alongside this is the ATEX Notified Body’s identification number. The other difference is the ATEX requirement for the Explosion Protection symbol ![]() and coding string for Equipment Group, Equipment Category and Environment, G and/or D (Gas/Dust). The information given in the extra coding string can easily be deduced from the other information already included for both ATEX and IECEx Product Marking.

and coding string for Equipment Group, Equipment Category and Environment, G and/or D (Gas/Dust). The information given in the extra coding string can easily be deduced from the other information already included for both ATEX and IECEx Product Marking.

The team at Ex Dynamics have vast experience of design and manufacture for hazardous areas. Our intimate knowledge of ATEX and IECEx, as well as North American certification, allows us to quickly develop world beating products for our clients or assist them on their hazardous area journey.

If you have any product development requirements, or would just like to understand more about what Ex Dynamics can do for you, please get in touch.